REFERENCES

Volkswagen AG

Best Practice: Design of New Ergonomic Line at VW in Salzgitter Based on MTM and EAWS

17.11.2017

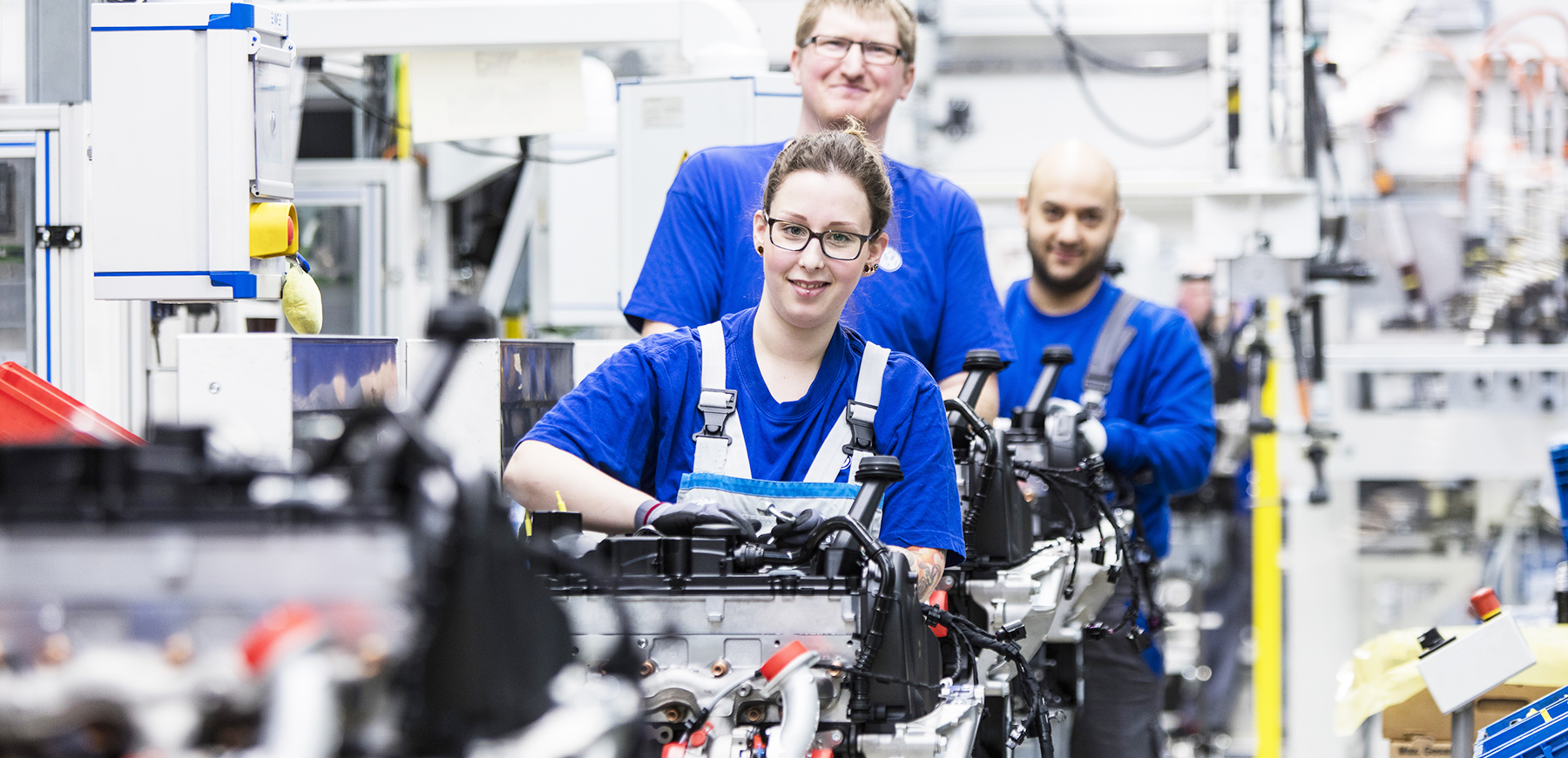

The new assembly line at the VW engine factory in Salzgitter is causing a stir as an ergonomically designed line. The work stations have been designed with the help of MTM and the ergonomic assessment process known as EAWS; as a result, they take into account the age of workers and the aging process; and even workers with reductions in their mobility can make a sensible contribution to the operating results here. Employees aged 50 and over, those with an irreversible sickness and younger employees are all put to use on the ergonomically designed assembly line – each group accounting for one third of workers. Particularly in the light of the process of demographic change and the increasing shortage of skilled workers, the all-round approach of MTM on work system design – i.e. observing ergonomics and productivity together – has proved once again to be the key factor for ensuring long-term economic success and motivated, valued employees.

The project team consisting of specialists and managers from various operational functions, which supported the planning and implementation of the new assembly line in Salzgitter, was primarily guided by the needs of the employees. This also meant involving the workforce in the design process from the outset. “More than 200 employees were questioned about their experiences on the old assembly line,” says Otto Lang, Head of Industrial Engineering at Salzgitter. The information and suggestions for ergonomic improvements that were received were verified with the help of MTM and EAWS and were directly included in the planning work for the new assembly line. For example, workpiece holders that can be swivelled and with adjustable heights, shock-cushioning seats, height-adjustable electric screwdrivers and optimized lighting for the workplaces are all now available.

Design starts as early as the production development stage

“It was important for us to already adopt the right course in the early phase of the product emergence process,” Lang emphasized. Some influence was exerted on the product design, for example, in order to prevent costs caused by assembly bottlenecks or awkward handling of components from the outset. Other measures that make the new assembly line an ergonomically designed one concern the organization of work. The corporation now has, for instance, seated workplaces and pre-assembly places that are not linked to the line balancing system for employees with an irreversible sickness as well as work stations where the robot takes over particularly arduous activities from an ergonomic point of view. The procedure for optimizing ergonomics and productivity at VW in Salzgitter is due to be continued with CIP phase workshops this year and next year too.

Picture Copyright:

© Volkswagen AG