REFERENCES

Schaeffler Technologies AG & Co.

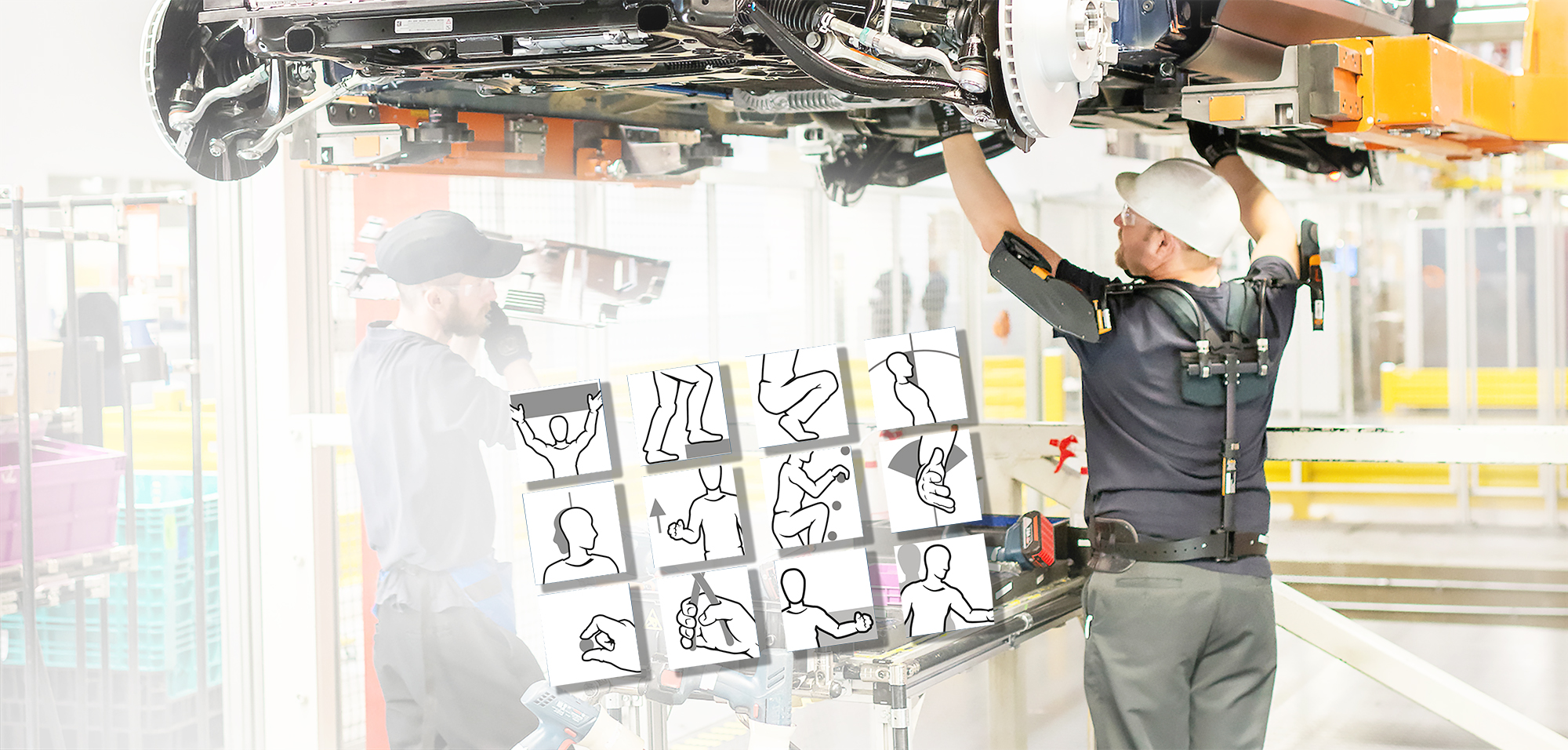

BSH, Kiekert and Schaeffler Test the MTM-HWD® Process Building Block System

16.10.2018

The partners in the Human Work Design (HWD®) development project – Audi, Daimler, Miele and VW – are currently in the process of validating the new MTM-HWD® process building block system and gaining experience in its use in corporate practice. Three new users – Kiekert, BSH and Schaeffler – attended the 50th working group meeting at Erfurt in September. The gathering focused on assessing the degree of maturity of the process building block system, new features for the analysis procedure and gaining new users.

The corporations and academic partners using the system all agree that MTM-HWD® supports industrial engineering and enables it to arrive in the age of digitalization. After all, MTM-HWD® supplies and structures the elementary raw material of the digital age: data. While classic MTM process building block systems are primarily used by work planners, MTM-HWD® is designed for use by several operating departments: ranging from time management to ergonomics/corporate health management/the company physician, product development and design and even the human resources department and improvement management.

The most important new features that were discussed in Erfurt include the introduction of more pictograms for objects and actions. Modelling templates for faster and more accurate analysis work were also presented. A further innovation involves the assessment of work content caused by design – eHPU (engineered hours per unit) – which is also possible on the basis of an HWD® analysis. As partners like Miele are already introducing the new process building block system outside Germany, e.g. at the corporation’s factory in Uničov (CZ), teaching materials for training people in MTM-HWD® are already available in German and Czech.

Here are the benefits of using MTM-HWD® again at a glance:

- One application, but three results: work process, time, ergonomics

- Any changes in the output data are immediately visible in all the results

- The major focus of the application is on design

- Fewer analysis errors because of the integrated rules in the software

- Easier to understand because pictograms are used

- Simpler to transfer to foreign business locations (training, discussions, etc.)

- MTM-HWD® can be integrated as a TiCon application in the IT landscape

Picture Copyright:

© BMW Group

Schaeffler Technologies AG & Co.

BMW and Schaeffler: MTM-Practitioner Customized

17.07.2018

Corporations Benefit from New Training Concept in Several Ways

Communicating well-founded knowledge in a sustainable and cost-efficient manner – that is what corporations require in any contemporary employee qualification program. Deutsche MTM-Vereinigung e. V. is going one step further in its MTM-Practitioner training. Firms are able to kill three birds with one stone – practical training, specific project work and direct incorporation in ongoing operations – by using the in-house training option and the associated integration of topics that are particularly suitable for the corporation. The pioneers of this customized training concept are the MTM member corporations, BMW AG and Schaeffler Technologies AG & Co. KG.

The practical elements are the key part of the in-house MTM-Practitioner training courses. BMW AG is focusing on the varied work station elements in its training center at the BMW Production Academy. The participants are given a specific task, e.g. on waste, the process notice board or Kanban and are able to work on them live at the individual work points. Using the company’s MTM process building block system plays a central role here. The results achieved at the work stations like the MTM analysis, line balancing diagram, production times and key performance indicators on cost-effectiveness as well as the knowledge gained from them are then discussed and documented together following an exercise. The exchange of ideas among the participants on specific factory circumstances promotes an all-round understanding and paves the way for a standardized procedure.

BeGreifen (meaning understanding or grasping) is the buzz word for MTM Practitioner training at Schaeffler. Learning from use in practical operations and gaining experience are the primary tasks here. The participants have to prove their skills in small projects as part of their MTM-Practitioner training. The focus here is on getting to know and testing operating procedures, preparing the relevant documentation and using methods and software tools in the operational production system. In addition to any familiarization geared towards involving employees, the corporation primarily benefits from the results of the individual projects. The customized design of the five-day training course is based on the general conditions for MTM Practitioners, the content and organization of which is defined in the Training and Examination Rules.

The benefits for the corporation are obvious:

- Being able to use the MTM process building block systems in a familiar environment and on established work processes makes it easier to understand the principles.

- The instructor or trainer has the opportunity of using internal documents.

- The project, which is being processed as part of the MTM Practitioner training course, can be immediately introduced after this.

- Participants from different corporate sites have the opportunity of getting to know about the processes at the other factories and are then able to take with them good ideas from the factory performing the work and use them at their own site. This gives rise to classic win-win situations.

- The motto is: practical training on the shop floor, instead of theory in the classroom.

- In-house, corporate MTM-Practitioner training courses create a win-win situation for the company and employees at the same time.

Picture Copyright:

© BMW Group