REFERENCES

Miele & Cie. KG

Miele Relies on Company-Specific MTM Standards

13.02.2018

Best Practice in Single-Part and Small Batch Production

Whether corporations are involved in mass, batch or single-part production – MTM provides the suitable building block system for each type of process. This is proving to be highly useful for the Miele corporation at its factory in Bürmoos, Austria, too. The challenge in the medical engineering division is to plan particularly extensive work content with just small numbers of items – and still keep expenditure as low as possible. The industrial engineering department there was confronted by the issue of whether MTM could be used in a cost-effective manner for planning purposes in the medical engineering sector.

In order to answer this question, it first made sense to take a look at what was happening outside the box – in a sector that handles challenging work content and numbers of items: the air freight industry. Deutsche MTM-Gesellschaft mbH established contact with the MTM member corporation, Airbus Defence & Space in Manching. The planners there had just subjected the maintenance of the Eurofighter aircraft to close scrutiny and achieved ideal results by using MTM to calculate testing procedures. The approach adopted there benefited the time management experts at Miele.

Developing a company-specific process building block database

Based on MTM-MEK, the process building block system for single-part and small batch production, they developed company-specific MTM standards jointly with Deutsche MTM-Gesellschaft mbH. “Our MTM process building blocks are product-related and therefore form the ideal prerequisite for speedy and accurate time calculations,” says Thomas Heinze, Head of Industrial Engineering in the Professional Technology Division at Miele & Cie. KG, explaining the situation. The MTM-MEK process building block system is ideally suited as the basis, because no detailed information about motion sequences is necessary to draw up the planning analyses or to model target sequences in assembly work. It is enough to know about general conditions like distance classes, the type of provision of parts in the work system as well as the positioning accuracy and the weight of the components in order to determine the factors that influence times. Ergonomics was also observed separately from the building block system – on a case-by-case basis and where necessary.

The results were better than expected

“MTM not only enabled us to significantly improve our basis for planning. Our expectations with regard to optimizing the process through layout and workplace design were exceeded", Heinze emphasized. “The assembly times that have now been calculated were significantly lower than the previous ones. We’re not just continuing to develop the products, but the work system and the supporting processes on a permanent basis too", says the IE manager.

Cost prevention instead of cost reduction

In his view, using the MTM process language achieves success that goes far beyond the issue of time – e. g. it provides important design information to optimize the methods. And there is another benefit too. “Company-specific process building blocks have become so easy to use because of their relationship to the product that you don’t need to be an industrial engineer to configure product options, for instance. We’re now able to respond to special customer requirements faster. All in all, we now have a very flexible system for planning dates and capacities or making calculations", says Heinze with a sense of conviction. “We’ve also been able to derive direct ideas for planning in other divisions from the projects that we’ve handled so far. We’ve made use of the opportunity of becoming involved in the product development stage very early too and therefore continuing to improve the design of our products to take production into account", says the IE manager. “This is helping us prevent costs from the outset.” The corporation is currently working on transferring the newly established building block system to other product lines that involve small numbers of items in the Professional division.

Exact planning for human resources and dates

Heinze summarizes matters in this way. “Using MTM in the production environment for single parts and small batches with the relevant degree of organization is an outstanding success with the MTM-MEK analysis system. MTM supplies objective results; as a result, human resources capacities and dates can be planned precisely on this basis.”

Picture Copyright:

© Miele Werk Bürmoos GmbH

Miele & Cie. KG

20 Years successfull with MTM

15.08.2018

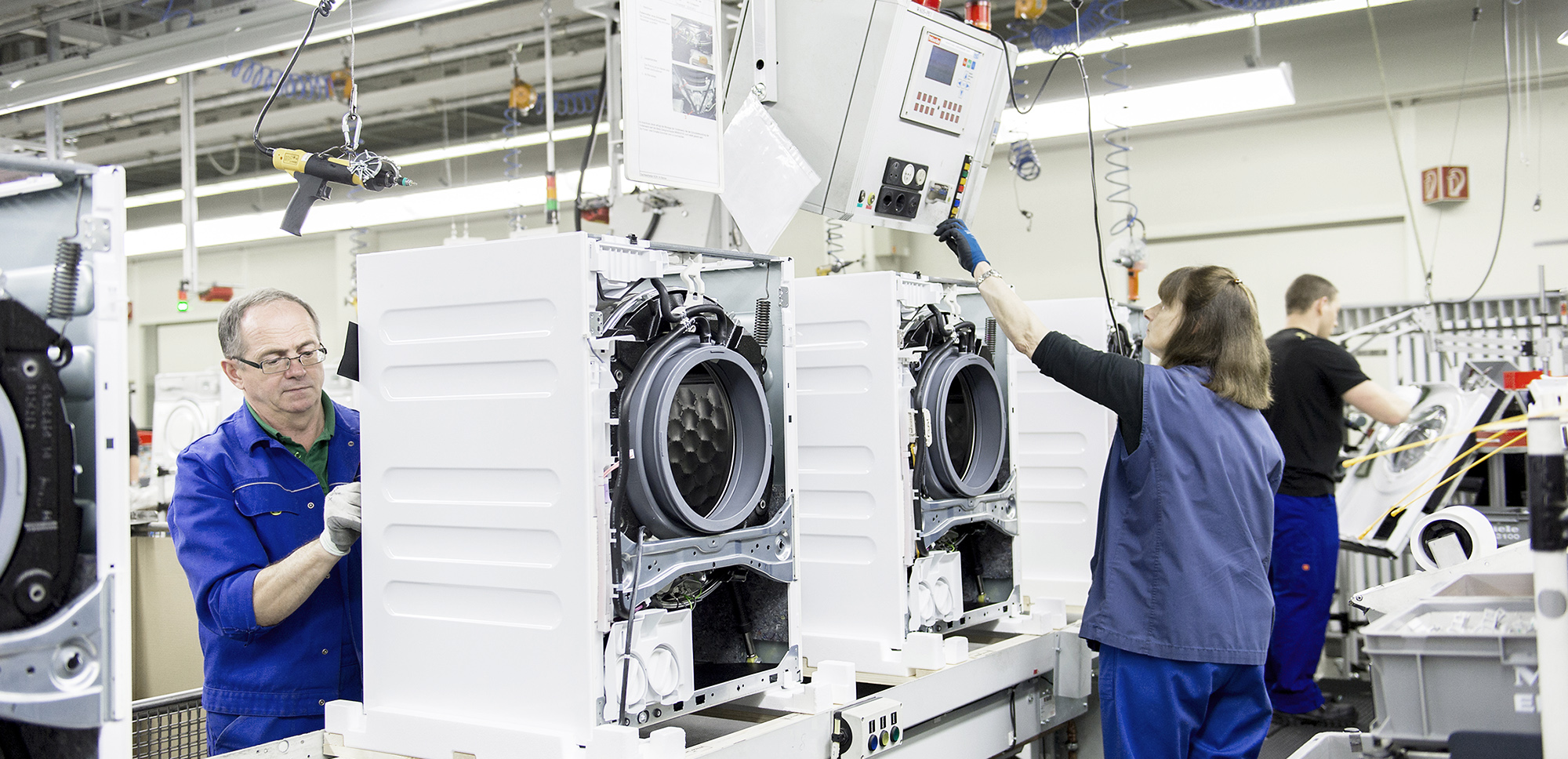

Using from MTM-1 to MTM-HWD®

Miele & Cie. KG has been relying on MTM tools and software to plan, design and optimize processes and products for more than 20 years. As a member corporation of Deutsche MTM-Vereinigung e. V., Miele has also repeatedly made its innovative capacity available for the business of continuing to develop the process language – most recently with the introduction of MTM-HWD®. The new MTM process building block system combines methodical and ergonomic work design in just one step – that is to say, only one analysis is required to provide three results – a description of the process, the time and an assessment of the ergonomics.

Miele is a partner in the development project Human Work Design (HWD®) and has made a significant contribution to the successful development of HWD® with the extensive practical testing of the new modular system in assembly. The Miele managers were expecting conclusive information from the analysis about how it is possible to harmonize work design and productivity development – and take ergonomics into account – and also productively make use of older employees in a line-balanced, continuous flow assembly process.

All the production lines at the Miele factory in Gütersloh have now been switched to using MTM-HWD®. The system is now being introduced at the press plant and in the field of preassembling component modules. The corporation is also introducing the process building block system outside Germany – for example, in the factory at Uničov (CZ). These factories are motivated to introduce MTM-HWD® because of the mixture of benefits involving ergonomics, performance and the promotion of learning at workplaces.

Preventing negative consequences for health by using MTM-HWD®

The articles published in the newsletter from the corporate health management department and in the factory newspaper about MTM-HWD® illustrate that even the works council at the factory in Gütersloh supports the use of MTM-HWD® and this is having an effect on employees. The “Health” section of the factory newspaper in Gütersloh contains the following information: “HWD enables us to recognize better where particular movements are unbalanced and workloads are too high. On this basis, we can change procedures and working stages and reduce negative consequences on people’s health and, at best, even prevent them occurring at all… Following a test phase on the WAo6 assembly line, which continued for one year, we’ve been using the system since April 2016. A sports scientist initially showed the employees how to act in an ergonomically positive manner at the work stations and practised this with the participants. At the same time, three groups discussed the requirements and what was needed to ensure that movements become easier.”

The article in the Newsletter for Corporate Health Management (BGM) has the following title: “Analyzing Work Stations: Now with Human Work Design.” The article explains that productivity and ergonomics are the two aspects that can now be analyzed simultaneously for the first time through the HWD procedure that is being used at the GTG factory. Standardized times and a points system, which quantifies the ergonomic workload of individual work procedures, form the basis for the analysis work.

A positive response from the works council and the workforce

“We were already able to optimize some procedures with the employees during the pilot project on line 6 in this way. We worked closely with the corporate health management (BGM) on this and the positive response from the workforce shows us that we’re on the right track with HWD,” says Ralf Graute, who is a member of the industrial engineering department in Gütersloh. Heinrich Schlautmann, the deputy chairperson of the works council, observes, “We’re better able to recognize now where particular movements should be changed or prevented by using the HWD analysis tool – for example, to prevent unbalanced workloads. Work station rotation is another tool that is needed here. Employees can also learn how to screw items with both hands alternately, for example, which is a challenge that people gladly accept for their own health’s sake.”

Working methodically and systematically and not haphazardly

The all-round process of designing work systems with MTM is also a topic at the specialist conference at Miele in Gütersloh on 22 August 2018; this occasion will also be used to wish Dr. Ernst Krämer, Head of Strategic Projects for Appliance Production, all the very best for his retirement. Krämer, who is the Chairman of the Board at Deutsche MTM-Vereinigung e. V. until the end of this elected period, has closely followed the use of MTM at Miele during the last few decades. His guiding principle is this. “What you do not measure, will not change in the long term.” “This is also one of the fundamental topics at MTM – a subject that not only affects the design of individual workstations, but the complete product emergence process,” Krämer said in an earlier interview. “The most important issue, however, is that corporations use a methodology that has a systematic structure and is not subject to random procedures. This is the only way to be in a position to cope with the challenges posed by productive and healthy work.”

Picture Copyright:

© Miele & Cie. KG